In a significant shift in its manufacturing strategy, Tesla has announced that it will phase out the front die casting for the new Model Y. This decision is part of an overarching strategy to streamline production processes and improve the efficiency of its vehicles. By optimizing the rear die casting process, Tesla aims to achieve a reduction in overall vehicle weight, ultimately enhancing performance capabilities and increasing production output.

The new Model Y has garnered attention for its innovative manufacturing methodologies, particularly in the realms of die casting. Traditionally, Tesla has relied on die casting techniques to produce large sections of its vehicles as a means of simplifying assembly and reducing production times. However, with the latest updates, the company is seeking to balance the efficiency of die-casting with the need for flexibility in manufacturing various vehicle components.

Impact of Eliminating Front Die Casting

The decision to eliminate the front die casting is not without its implications. By moving away from this integrated design, which has been a hallmark of Tesla’s approach in recent years, the company is acknowledging the evolving landscape of automotive manufacturing and the specific requirements that the new Model Y poses. The front section will now be produced using more traditional methods, which allow for easier modifications and upgrades as battery technology progresses.

This shift will enable Tesla to maintain greater control over the production process while allowing for quicker adaptations to the design of battery housings and other essential components. Industry experts have noted that this decision reflects a broader trend within the automotive sector, where manufacturers are increasingly adopting iterative design and production processes to stay ahead of technological advances.

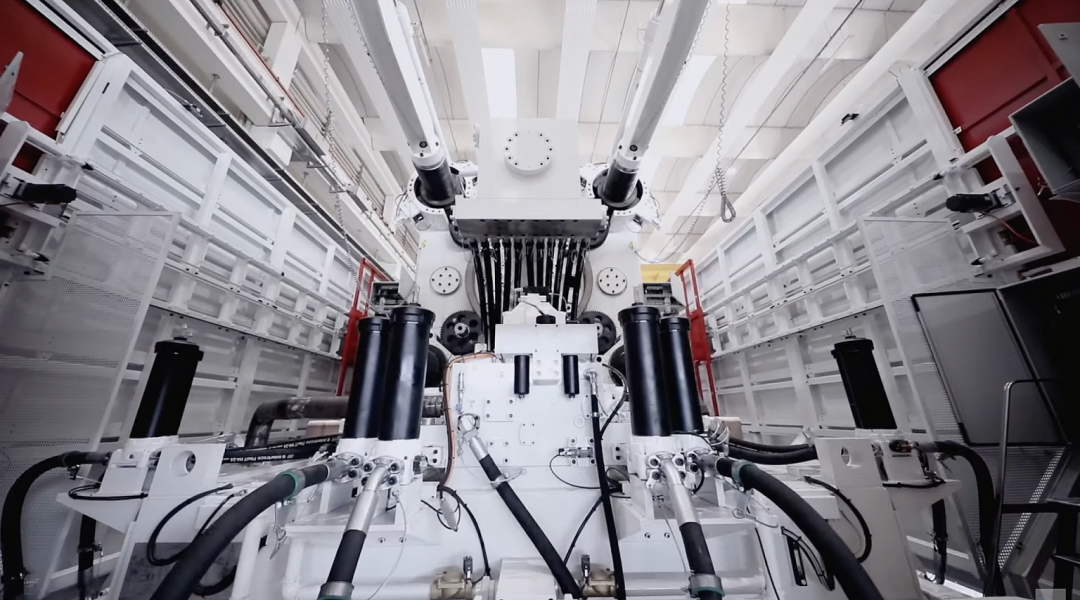

Enhanced Rear Casting Process

While the elimination of front die casting is a notable change, the optimization of the rear casting process is expected to yield significant benefits. Tesla has invested considerable resources in refining this aspect of manufacturing, enhancing the casting quality while reducing lead times. The optimization of the rear die casting process employs advanced techniques that allow for improved insulation of the vehicle’s battery pack.

Tesla’s focus on rear die casting also emphasizes weight reduction, which is critical for electric vehicles. By streamlining the design and manufacturing methods, Tesla aims to improve not only the efficiency of the Model Y but also its range and overall performance metrics. The optimization of rear casting techniques incorporates lightweight materials which critically contribute towards achieving these goals.

Future of Battery Technology at Tesla

As the electric vehicle landscape evolves, Tesla is poised to leverage new battery technologies that could significantly alter the design and functionality of its vehicles. Future updates to the Model Y may bring back the integrated front and rear die casting design, contingent on advancements in battery architecture.

With innovations such as the 4680 battery cell, which promises to deliver higher energy density at a lower cost, Tesla is preparing for a future where vehicle capabilities can be enhanced through better battery integration. This is expected to be a game-changer, particularly in how manufacturers approach the structural design of electric vehicles.

Tesla’s adaptability is key as it continues to lead in the transition toward sustainable automotive technologies. The company’s commitment to ongoing improvements in manufacturing processes, material use, and battery technology will likely shape the trajectory of electric vehicles for years to come.

Conclusion

The decision to eliminate the front die casting on the new Model Y highlights Tesla’s constant evolution in response to market demands and technological advancements. By employing traditional methods for the front section while optimizing the rear casting process, Tesla is set to address challenges while maintaining vehicle performance and production efficiency.

As the automotive industry moves forward, such changes are reflective of the broader shift towards innovative manufacturing approaches that can withstand rapid technological changes and a more demanding consumer base. Keep an eye on Tesla as it adapts and leads the way in redefining electric vehicle capabilities.